Systematic efficiency: how SMEs boost performance with limited resources

Every day, small and medium-sized enterprises face the same challenge: achieving maximum results with limited resources. While large corporations have entire departments dedicated to process optimization, SME leaders juggle daily operations, customer care, and strategic planning. The good news? Improving efficiency in SMEs works differently—and often more effectively—than in big companies. Short decision-making paths and flat hierarchies allow for rapid changes that deliver immediate, tangible results. In this article, you'll learn how to systematically enhance your processes, save time, and involve your team every step of the way. From initial analysis to lasting implementation, we’ll guide you through a proven approach to sustainable efficiency gains.

What efficiency improvement means for SMEs

Working more efficiently essentially means achieving better results with the same resources. For SMEs, this means concretely: accomplishing more with the same number of employees, the same budget, and in the same time – or achieving the same results with less effort.

Unlike abstract concepts, process efficiency in medium-sized businesses is about tangible improvements:

Time savings: When preparing a quote takes only one hour instead of three

Error reduction: When invoices are created correctly the first time

Customer satisfaction: When inquiries are answered within 24 instead of 72 hours

The numbers speak clearly: According to the KfW SME Panel, SMEs spend an average of 7% of their working time on bureaucratic tasks alone. In a 40-hour work week, this equals almost three hours per employee – time that's missing for value-creating activities.

Typical obstacles in small and medium-sized enterprises

Before you can begin optimization, it helps to know the most common stumbling blocks. These obstacles often develop gradually over years and only become visible when they're already burdening daily operations.

Obstacle

Concrete Impact

Unclear responsibilities

"Who actually handles vacation coverage?" – Tasks remain undone or are completed twice

Lack of digitization

Invoices are printed, signed, scanned – 15 minutes per process

Information silos

The sales department doesn't know what service promised the customer

Habit instead of system

"We've always done it this way" – even when better methods exist

A typical case example: A medium-sized craft business spends two hours daily coordinating orders between office and technicians – via phone, WhatsApp, and handwritten notes. The result: Double trips, forgotten materials, and frustrated customers.

How to start with process optimization

The first step toward efficiency improvement is often the hardest. Where to begin when improvement is needed everywhere? The answer: With system and in small, manageable steps.

1. Analyze current state

Before you can improve anything, you need a clear picture of the current situation. Choose a process that occurs frequently and where you suspect problems – such as quote preparation or invoice processing.

Document the actual workflow, not the theoretical one. Follow a task from beginning to end and note:

Who is involved?

What steps do the participants perform?

How long does each step take?

Where are there waiting times or follow-up questions?

A simple flowchart on paper or in a mind mapping tool like MindMeister makes weaknesses visible that get lost in daily operations.

2. Identify immediate actions

Quick wins are small improvements with big impact. They cost little time and money but show results quickly. This motivates your team and creates acceptance for larger changes.

Examples of typical quick wins:

Email templates: For frequent inquiries like quote requests or appointment confirmations

Checklists: For recurring processes like new customer onboarding or project completion

Fixed times: For concentrated work without interruptions

These measures for working time reduction through automation may sound simple, but their impact is measurable. A study by Datadus shows: Through intelligent workflow optimization, SMEs can save up to 45% of their working time.

3. Involve team in the process

Your employees know the daily workflows best. They know where things get stuck, what detours are necessary, and often already have ideas for improvements. Using this expertise is the key to success.

Create space for suggestions – whether in a workshop, an open Q&A session, or a digital idea board. The question "What annoys you most about your daily work?" often brings surprising insights.

Importance of automation and digital processes

Digitization offers SMEs today opportunities that were previously reserved for large corporations. Process optimizations don't have to be budget busters. With the right digital tools, major positive changes can be achieved for little money and time.

1. Workflow automation for SMEs

Workflow automation sounds complicated but simply means: software takes over recurring tasks. Instead of manually checking every morning which invoices are due, the system reminds automatically. Instead of sending vacation requests back and forth via email, approval runs digitally.

Processes that are particularly well-suited for automation:

Invoice workflow: From creation to payment reminder

Onboarding: New employees automatically receive access and documents

Procurement: Falling below minimum stock levels triggers order suggestions

2. Relevant tools for process efficiency in medium-sized businesses

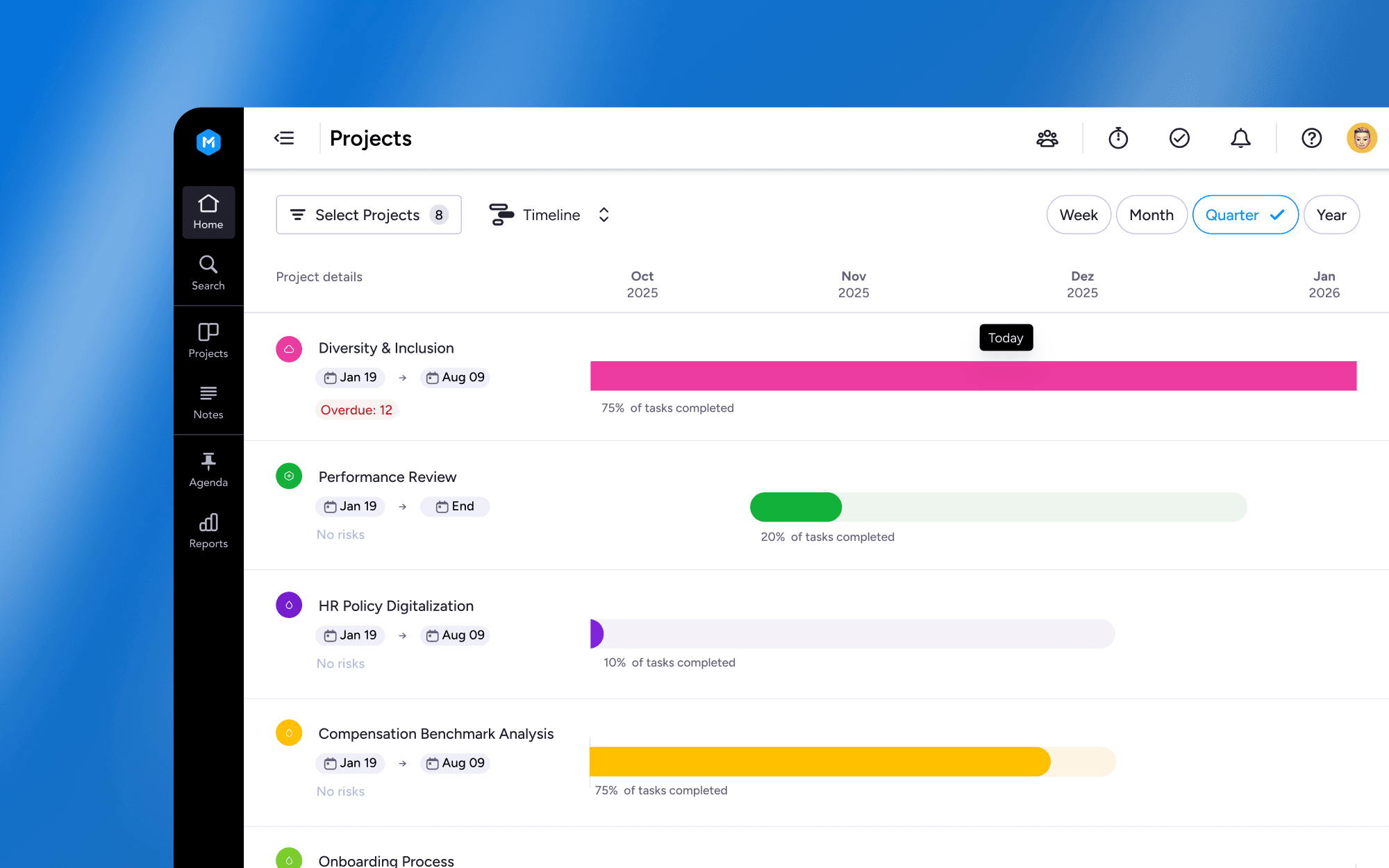

The right software makes the difference between chaos and structure. Project management tools like MeisterTask bring order to daily work. Instead of distributing tasks via email, all participants can see at a glance who is doing what by when.

The advantages of digital processes become apparent quickly:

Information is centrally available instead of scattered across various email inboxes

Progress is automatically documented

Responsibilities are clearly defined

3. Data protection and ISO certifications

When selecting digital tools, data protection plays a central role. Especially when working with customer data or sensitive company information, you need reliable partners.

Look for:

GDPR compliance: Hosting in Germany or the EU

Certifications: ISO 27001 for information security

Transparency: Clear information about data processing and storage

Tools like MeisterTask meet these requirements and offer German SMEs a secure foundation for their digital transformation.

Practical steps for continuous working time reduction

Saving time through process optimization for SMEs – that sounds good, but how do you implement it concretely? The following steps have proven successful in practice.

1. Time saving through process optimization in SMEs

Start with standardization. When every employee creates quotes differently, not only does creation take longer – follow-up processing for queries also costs time.

Practical approaches:

Uniform templates: For quotes, invoices, reports

Clear process descriptions: Who does what in which order

Defined interfaces: How and at what point information is transferred

2. Efficiency improvement in SMEs with digital processes

The step from paper to digital may seem small, but the impact is enormous. Digital documents can be searched, accessed from anywhere, and automatically filed.

Concrete improvements through digital processes:

Search time: From minutes to seconds

Availability: Access even in home office or at customer sites

Version control: No more questions about the current version

Team integration and change culture

New processes only work if your team supports them. Change often initially creates resistance – this is normal and understandable. The key lies in how you design the change.

Successful change requires:

Transparency: Explain the why behind the innovations

Participation: Let your team help shape the process

Time: Provide space for adjustment and learning

Successes: Celebrate even small progress

A tip from practice: Start with a pilot team. When the first colleagues have positive experiences, this often convinces more than any presentation.

Long-term efficiency as a system

One-time improvements quickly fizzle out. Sustainable efficiency improvement occurs when you understand optimization as a continuous process.

Build structures that promote permanent improvement:

Regular process reviews (quarterly or semi-annually)

An open ear for improvement suggestions

Measurable metrics that make progress visible

Successful SMEs make efficiency part of their corporate culture. It's not about cleaning up once, but about maintaining order and constantly improving.

Take your efficiency curve upward

You now have the tools for systematic efficiency improvement. Time to put theory into practice. Choose a process, analyze it, and implement initial improvements.

With the right tools, this path becomes easier. MeisterTask helps you structure tasks, clarify responsibilities, and make progress visible.