ERP vs. project management? Why the real answer is synergy.

Why would you even need a project management tool if you already have an ERP system? Your ERP knows every part number, every order, every invoice. It keeps production running with precision and consistency. But if your lead technician suddenly drops out, your ERP doesn’t know which steps they usually take to solve problems. It has no access to informal agreements, quick decisions, or knowledge built from years of experience. That’s where the gap lies: processes are covered — projects are not.

What sets ERP apart from project management?

An ERP system (Enterprise Resource Planning) is the backbone of many manufacturing companies: resources, finances, inventory — everything is documented with precision. But when it comes to projects, ERP quickly reaches its limits. Projects are dynamic, full of dependencies and decisions that don’t fit neatly into spreadsheets. That’s where the difference becomes clear: ERP and project management software are not competitors, but two sides of the same coin. The key question is: how can companies combine both systems so processes run smoothly — and projects truly succeed?

Aspect

ERP systems

Project management software

Primary purpose

Managing company resources

Planning and controlling projects

Focus

Standardized processes

Flexible project workflows

Data-centered

Transaction data, finances

Tasks, progress, communication

User groups

Entire organization

Project teams

Adaptability

Rigid, extensive configuration

Flexible, quickly adaptable

The core differences are most evident in three areas:

ERP systems: focused on resources, finances, and standardized business processes

Project management: centered on teamwork, task planning, and flexible workflows

Data structure: ERP relies on structured transaction data, while PM tools work with collaborative content

Where do ERP systems fall short in projects?

ERP systems encounter natural limitations when it comes to project work. The biggest challenge is “tacit knowledge” — valuable experience and expertise stored in the minds of long-term employees but documented nowhere.

Lack of flexibility

ERP systems excel at managing linear processes. But projects don’t run on an assembly line — they are dynamic, full of uncertainties and dependencies. That’s where ERP solutions start to struggle:

Rigid process flows make quick adjustments difficult

High configuration effort for even small changes

Long implementation cycles for new requirements

For example: a machinery manufacturer is developing a new product. The ERP knows every material number and delivery date. But if the customer requests a last-minute change, it can take weeks to adapt the system’s processes. In the meantime, the project team improvises daily — relying on Excel sheets or ad-hoc meetings.

Collaboration shortcomings

ERP systems are built for transactions — not for teamwork. They document numbers and resources but don’t foster collaboration. Interfaces are often clunky, require extensive training, and discourage everyday use. Spontaneous check-ins, quick decisions, or strategy workshops simply can’t be mapped in an ERP system.

Lack of project insights

Even when all data is stored in the ERP, it often remains invisible to project teams. Information is scattered across different modules, leaving no clear view of project status. Visual tools like Kanban boards or progress indicators are typically missing in ERP systems. The result: teams lose oversight, dependencies are overlooked, and delays escalate.

Why project management software perfectly complements your ERP system

Project management software closes the gaps ERP systems leave in project work. Both systems work hand in hand: ERP manages resources and finances, while PM software supports teams in their daily work.

While your ERP system provides a reliable, data-driven foundation for planning and administration, a project management tool like MeisterTask delivers the agility needed in day-to-day operations:

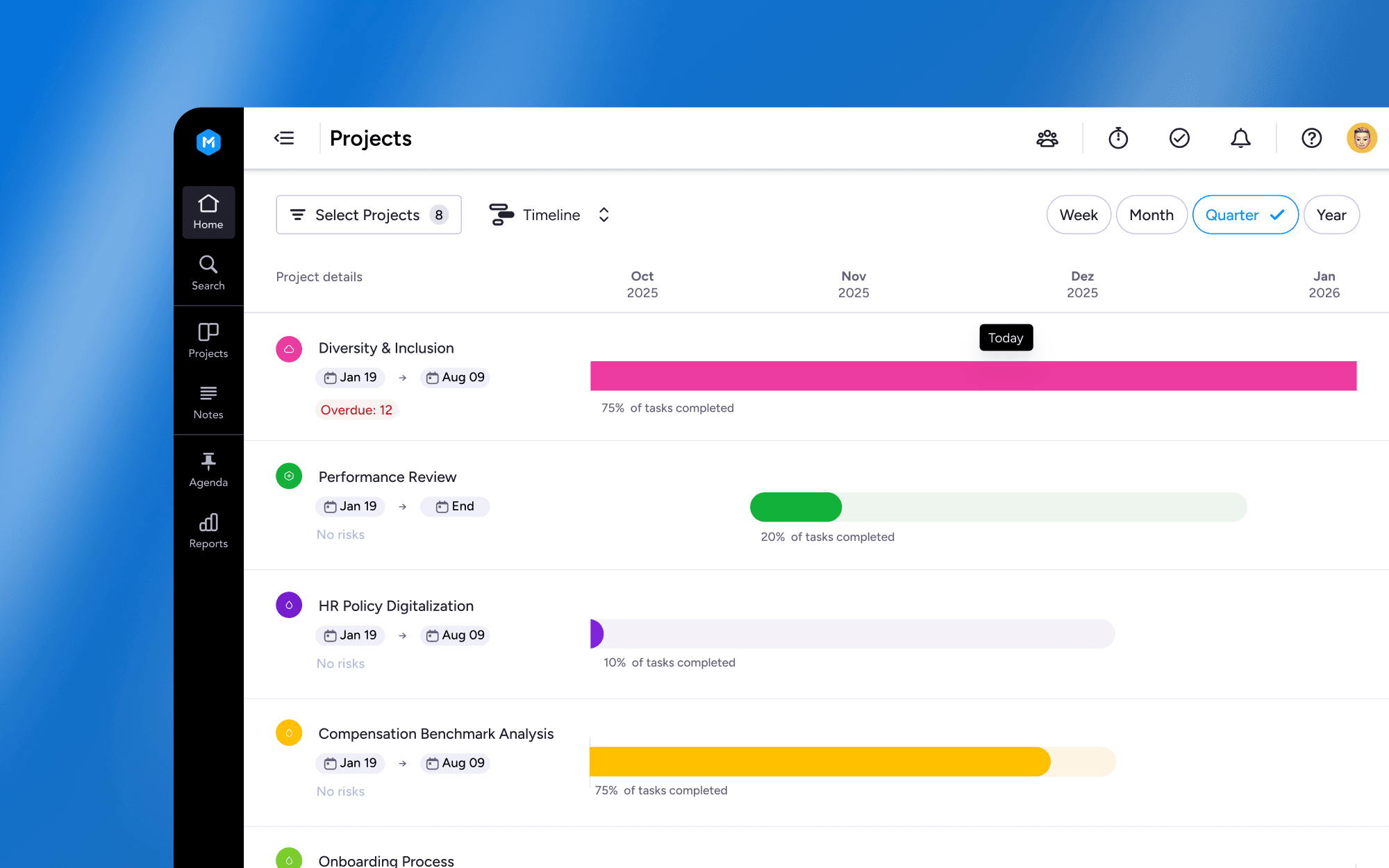

Transparent task planning: Kanban boards or Gantt charts instantly show who is working on what and what’s coming next.

Real-time progress: delays become visible before they escalate. Dashboards make project status transparent for everyone.

Central knowledge base: experience, decisions, and best practices are no longer lost but documented and accessible to the entire team.

The combination makes all the difference: ERP ensures structure, while the project management tool drives momentum. Only together do both systems provide the foundation for sustainable project success.

How to successfully combine ERP and project management software

Many companies ask themselves: duplication or synergy? The answer is clear — synergy. An ERP system and project management software are not rivals but partners. The art lies in distinguishing the strengths of each system — and then connecting them deliberately.

Here’s how collaboration works in practice:

Clear division of roles: your ERP remains the authority for finances, resources, and standardized processes. The project management tool takes over operational project control — from tasks and deadlines to responsibilities.

Connected data flows: modern interfaces ensure that budget and resource data from the ERP flow into the project management tool. In turn, time tracking and project progress data are sent back to the ERP.

Unified reporting: instead of creating isolated reports, combine data from both systems. This way, you get a complete picture — from operational project status to financial impact.

The result: fewer silos, more transparency. Your ERP provides stability, your project management software provides speed. Together, they create the foundation for predictable processes and successful projects.

See how this works in practice in our customer story with Verwo: the company combines ERP and MeisterTask to manage projects with full transparency and efficiency.

How do you preserve valuable team know-how?

In manufacturing, ERP systems manage linear processes with precision. But they can’t capture the experience of your senior technician who has spent 25 years mastering tricky problems. This tacit knowledge lives in people’s heads, not in systems — and it risks being lost when employees retire, leave the company, or are simply absent.

That’s why, when building your knowledge databases, you should keep the following in mind:

Knowledge transfer: capture the expertise of experienced employees in your project management tools.

Documentation: record processes, decisions, and solutions in a structured and transparent way.

Accessibility: make stored knowledge available and usable for all team members.

MeisterTask offers an integrated Notes feature that lets you collect and share collective know-how. This way, your knowledge base can grow with your company. Learn more about Notes.

Data protection and compliance: why security is essential in project management

For manufacturing companies, security is not just a requirement but also a key competitive factor. ERP systems are already designed with data protection and compliance in mind — but once projects take place outside the ERP, a gap emerges. When project information circulates in emails, Excel sheets, or unsecured tools, you risk exposing sensitive data and violating internal policies or legal requirements.

A professional project management solution like MeisterTask closes this gap:

GDPR-compliant and hosted in Germany: all data is stored on servers that meet the highest European security standards.

Certified security: ISO 27001, C5, and SOC2 certifications ensure your data is protected at all times.

Granular access rights: you decide who can view and edit which information — making compliance the rule, not the exception.

This way, you retain control not only over your projects but also over your data. Your ERP guarantees secure processes — your project management tool ensures that this standard is upheld in collaboration as well.

Synergy, not competition: delivering successful projects

ERP systems and project management software are not in competition — they complement each other perfectly. ERP forms the backbone of organizational processes, while PM tools enable agile project work.

ERP manages your processes. MeisterTask protects your know-how.