ESG in manufacturing: the key to competitiveness

Manufacturing companies are under growing pressure to meet Environmental, Social and Governance (ESG) requirements. Regulations such as the EU Corporate Sustainability Reporting Directive (CSRD) and Germany’s Supply Chain Due Diligence Act (LkSG) raise the bar even higher. At the same time, customers and investors increasingly view sustainable production as the key to long-term competitiveness.

Read on to discover why ESG is a real opportunity for production and manufacturing – and how modern tools help you stay in control.

ESG in the context of manufacturing: definition and opportunities

ESG stands for Environmental, Social and Governance. In manufacturing, it’s not just a challenge but a valuable opportunity. By actively managing energy and waste streams, taking social responsibility, and ensuring transparent governance, companies can cut costs, drive innovation, and strengthen their appeal to both investors and skilled workers.

Environmental: sustainable production through energy management

The environmental dimension covers all aspects related to energy, emissions, and resource use. According to Parsable, industry is responsible for 23% of global greenhouse gas emissions, with fossil fuel use in manufacturing contributing significantly to CO₂ output. In Europe alone, the sector emits 880 million tons of CO₂ each year. By implementing energy management practices such as audits, assessing green energy suppliers, or optimizing production processes, manufacturers can significantly reduce their carbon footprint while cutting costs.

Social: workplace safety in production and manufacturing

The social dimension evaluates how a company treats employees, suppliers, and society at large. For manufacturers, this means providing safe working environments and ensuring both staff and machine safety. ESG-minded investors look for companies that guarantee fair working conditions, health protection, and ethical sourcing. In practice, this often involves regular safety training, reducing workplace hazards, and improving overall working conditions.

Governance: transparency and risk management

Good governance goes beyond compliance. It includes independent supervisory boards, clear accountability, ethical business practices, and data protection. Strong governance helps manufacturers identify risks early, make decisions more transparently, and build trust. According to AuditBoard, companies with strong governance structures enhance both their credibility and their efficiency.

Why ESG is becoming essential in manufacturing

A mix of regulatory, societal, and economic factors is forcing companies to take ESG seriously and embed it into their operations.

Regulatory pressure and ESG reporting obligations

In recent years, sustainability has become a key concern — both in business and society. The EU, in particular, is holding companies increasingly accountable for their environmental and social practices. A key element of this shift is the CSRD, which requires companies to report comprehensively on their sustainability efforts.

Currently, the directive applies to large public-interest entities with over 500 employees. Starting from the 2025 financial year, all other large companies under accounting law are also included and must prepare for their first ESG reports in 2026. From 2026 onward, small and medium-sized enterprises listed on the stock exchange will also be required to publish detailed ESG data. As a result, the number of affected companies in Germany alone will rise from 550 to around 15,000.

On a national level, Germany’s Supply Chain Due Diligence Act (LkSG) requires companies with more than 1,000 employees to identify and mitigate risks across their supply chains. This includes early warning systems, complaint procedures, and regular reporting. Violations may result in fines.

Customer and investor expectations around ESG

ESG criteria have evolved from a “nice-to-have” into a foundational investment principle. Companies that prioritize ESG tend to perform better in the long term: they reduce the risk of fines, lawsuits, and reputational damage; foster employee wellbeing; and improve transparency and efficiency through sound governance. They also create a more attractive workplace that helps retain talent.

The numbers back this up: According to Parsable, 71% of CEOs see it as their personal responsibility to ensure that their ESG policies reflect customer values. Forty-four percent of companies say growth opportunities are the main driver of their sustainability programs, while 64% of manufacturers plan to ramp up their use of renewable energy.

Investors prefer companies with high ESG scores because they are seen as lower-risk and more future-ready.

Minimizing risk and increasing employer appeal

Strong ESG strategies help mitigate environmental risks and supply chain disruptions. Companies that professionally manage environmental factors tend to perform better financially and avoid legal costs. Since manufacturing is one of the largest emitters, it’s under particular scrutiny from regulators and the media. Companies that improve their energy and material efficiency early will be better positioned to avoid future levies and CO₂ pricing.

Common ESG challenges: from strategy to daily operations

Many industrial companies have ambitious ESG strategies, but struggle to put them into practice. Typical roadblocks include:

Lack of visibility: When projects are spread across emails, Excel sheets, and disconnected tools, it’s easy to lose track. Without clear structure, progress is hard to follow.

Unclear responsibilities: Without well-defined roles, it’s difficult to measure success and ensure accountability.

Data silos between departments: When systems aren’t integrated, collaboration suffers. This leads to lost information and delays.

Difficulties proving progress: ESG reporting requires documented proof. Without a centralized source of truth, collecting checklists, certificates, and audit records becomes much harder.

These challenges show that strategy alone isn’t enough. Practical tools and platforms are needed to unify information across departments and make ESG efforts easier to manage.

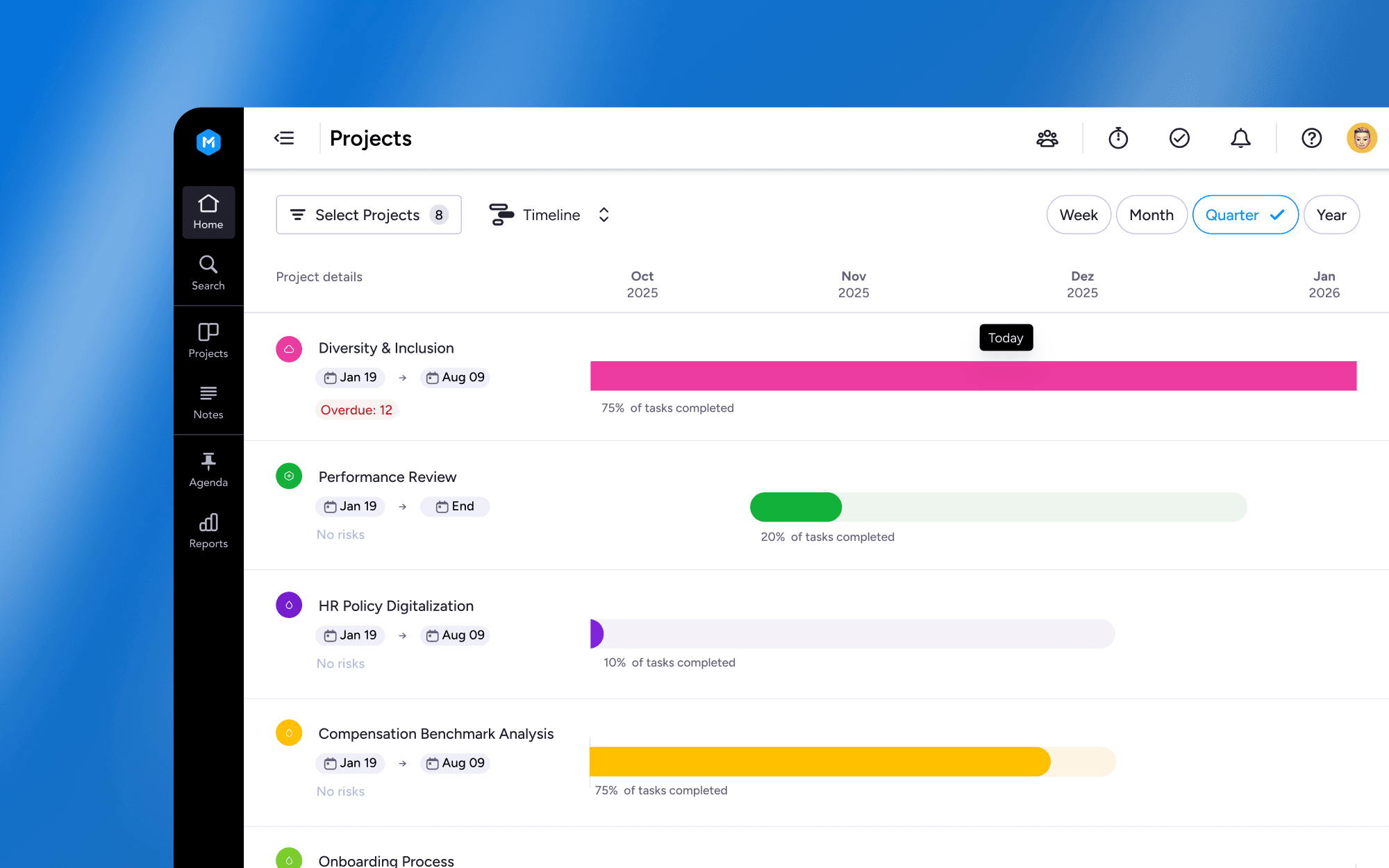

Managing your ESG strategy: How MeisterTask helps in practice

Integrating ESG principles into your manufacturing business requires clear structures and precise execution. MeisterTask gives you a central solution to manage and monitor all ESG activities. Close operational gaps and boost your ESG performance with a systematic approach.

Central project planning for all ESG initiatives

To manage your ESG strategy effectively, you need a structured overview of all initiatives. In MeisterTask, you can create a central Kanban board that visualizes your entire ESG process. A typical column setup might include:

Idea Backlog: Initial suggestions and concepts for ESG measures.

Planned: Measures scheduled for the next quarter.

In Progress: Ongoing ESG initiatives.

Review: Activities under review.

Completed & Documented: Finalized actions with supporting documentation.

This structure helps track progress efficiently and ensures all ESG goals are met on time.

You can also use a ready-made ESG Management Template specifically designed for manufacturing companies. This template helps you get started quickly while ensuring all relevant ESG criteria are addressed from day one.

ESG in manufacturing: a real opportunity for sustainable production

Success starts with structured organization. With a centralized platform like MeisterTask, companies can plan their Environmental, Social and Governance initiatives, assign responsibilities, visualize progress, and consolidate documentation.

If you want to see how other companies are using MeisterTask, check out our customer stories. One example: White Arkitekter, an architecture firm with more than 700 employees, needed a better way to manage complex projects. Outdated tools had led to chaotic workflows and frequent mistakes.

The challenge: unstructured workflows and error-prone processes

Numerous parallel projects with different requirements made it hard to keep track. Strict documentation standards and multiple stakeholders further complicated things.

The solution: meisterTask as the central project management tool

White Arkitekter introduced template-based Kanban boards that clearly structured each project. Automations reduced manual work, and clear task assignments meant everyone knew what to do.

The result: more efficiency and saved time

Thanks to MeisterTask and its automations, White Arkitekter streamlined project delivery and significantly reduced time spent on planning and coordination. The company reported major time savings and improved collaboration.