CIP: Continuous Improvement in Manufacturing

Manufacturers must reduce costs, maintain high quality, and meet ESG targets. The continuous improvement process (CIP) makes all of this achievable—step by step, not through sweeping transformations.

In this article, you'll learn what continuous improvement involves, why it's especially important in manufacturing, how the process is structured, and how digital tools can help create a culture of sustainable improvement.

What is continuous improvement (CIP)?

The continuous improvement process (CIP) is a structured approach to incrementally improving processes, products, and services. Unlike one-off optimization projects, CIP is an ongoing cycle of identifying problems or potential improvements, developing and testing solutions, and documenting successful actions as the new standard.

A defining characteristic of CIP is the involvement of all team members. The idea is that many small, team-driven improvements can generate real efficiency gains. The result? A workplace culture where continuous improvement is business as usual.

Roots in Kaizen and Lean

CIP is closely linked to the Kaizen philosophy—a Japanese mindset that focuses on small, people-driven improvements. Western business practices adopted Kaizen through frameworks such as the Toyota Production System and Lean Management, which aim to eliminate Muda (waste), Mura (inconsistency), and Muri (overburden) to streamline processes and improve competitiveness.

More than a one-time project

Unlike large-scale initiatives or cost-cutting programs, CIP is not a project with an end date. It follows the PDCA cycle (Plan–Do–Check–Act):

Plan: Analyze the problem, understand root causes, and define a clear goal.

Do: Test proposed solutions on a small scale.

Check: Measure results and compare them to the original goal.

Act: Establish successful measures as new standards and repeat the cycle.

This cycle ensures improvements are sustainably embedded into workflows and that processes stay flexible enough to adapt to changing demands.

Why continuous improvement matters in manufacturing

Manufacturers face high demands for output, precision, and cost control—especially in serial production. Small deviations can lead to serious inefficiencies: excessive inventory, downtime, or fluctuating product quality. Waste often hides in plain sight.

Despite having high improvement potential, manufacturing teams also face major barriers: departmental silos, rigid hierarchies, and lack of transparency. Many also work under formal quality management systems (e.g. ISO 9001), which require a commitment to continuous improvement.

CIP helps manufacturing teams:

meet high standards for efficiency and reliability

spot process weaknesses early

empower employees to contribute improvements

fulfill regulatory and customer expectations

The 6 phases of continuous improvement – from issue to impact

CIP typically includes six phases, aligned with standard quality management procedures:

Current state analysisStart by gaining a clear picture of how your process currently runs. This includes collecting relevant performance data, conducting on-site observations (Gemba Walks), and holding quick, focused shopfloor meetings. The aim is to observe real workflows, capture key metrics, and identify the root causes of inefficiencies. Transparent, visual documentation helps surface hidden weak points.

Goal settingBased on your initial findings, set clear improvement goals. These should follow the SMART criteria — Specific, Measurable, Achievable, Relevant, and Time-bound. For example: “Reduce the defect rate by 10% over the next six months.” Setting structured targets allows you to measure the success of your actions objectively.

Solution developmentIn this phase, you dive deeper into the root causes of issues and begin shaping practical solutions. Two tried-and-tested methods help guide this process:

5 Whys: Keep asking “why?” to dig beneath the surface of a problem until you uncover its true origin.

Ishikawa diagram (also known as the cause-and-effect or fishbone diagram): Visually maps out factors like materials, machines, methods, and people to reveal patterns and pinpoint areas for action. Once causes are clear, your team collects potential improvement ideas and evaluates them based on impact and feasibility.

Implementation and testingSelected actions are tested in pilot areas. The goal is to run small-scale experiments that limit risk while quickly generating feedback. Keep communication open throughout the test phase — document results clearly and measure outcomes against the defined goals to assess effectiveness.

Standardization and documentationIf a solution proves successful, it's time to make it official. Update standard operating procedures, training materials, and quality documentation accordingly. Using digital workflows here is a major advantage — all updates can be stored centrally, versioned properly, and accessed easily by your team.

Retrospective and lessons learnedAfter implementation, take time to reflect: What worked well? What challenges came up? How could the process be improved next time? Run structured retrospectives or lessons learned workshops to capture these insights. This knowledge helps refine future CIP initiatives and feeds straight into the next cycle of improvement.

Digital CIP in practice

Despite good intentions, many continuous improvement initiatives stall or fail entirely. The reasons are often the same: lack of transparency, unclear roles, no structure, and outdated tools like paper checklists or disconnected spreadsheets. When team members can’t track progress or see impact, motivation fades quickly.

A digital-first approach solves these issues at the root:

Built-in transparency: Every task, action, and KPI is tracked in a centralized workspace. Teams can instantly see who’s responsible for what, how far each initiative has progressed, and where support is needed.

Centralized documentation: Workflows, instructions, and process changes are documented digitally — searchable, versioned, and audit-ready. This makes compliance easier and ensures everyone has access to the latest information.

Seamless system integration: Modern platforms like MeisterTask connect with ERP, QA, and MES systems to sync data automatically. This minimizes manual input, avoids duplication, and ensures decisions are based on real-time information.

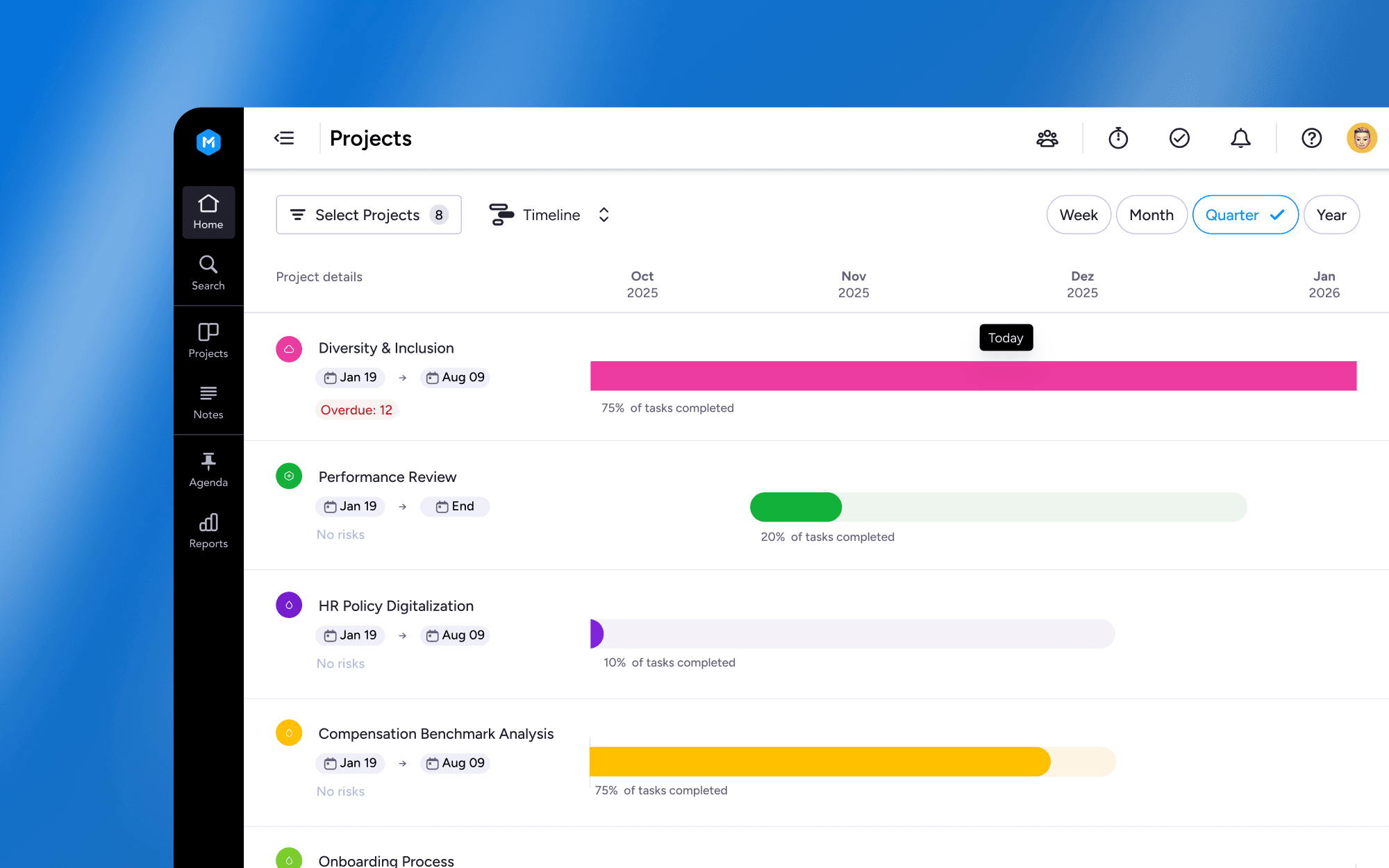

Kanban boards as a CIP hub

Kanban boards are a visual, transparent way to organize improvement work. Each card represents a task that moves through columns like "To Do," "In Progress," "Under Review," and "Done."

With MeisterTask, teams get a user-friendly platform hosted in Germany that combines task management, documentation, and collaboration. You can build a custom CIP workflow with just a few clicks and monitor improvement efforts across the board.

Real-world success stories

MeisterTask is already helping manufacturers across industries bring structure, transparency, and efficiency to their continuous improvement initiatives. These three examples show how real companies are using digital tools to optimize their operations:

Ritter Sport – Centralizing shopfloor communication At its plant in Waldenbuch, Ritter Sport faced delays due to disorganized paper lists and fragmented information. With MeisterTask, the company introduced a centralized digital task management system. Now, all teams can instantly see who owns which task and track open items during daily shopfloor meetings. The result: faster decisions, more efficient meetings, and a visible reduction in communication breakdowns.

FiSCHER – Digitalizing production and logistics workflows As a manufacturer with a strong logistics focus, FiSCHER needed a secure alternative to basic collaboration tools. With MeisterTask, the company now manages everything from invoice approvals and returns to fleet administration — all in one unified digital board. Automated workflows and integrated time tracking have replaced long email threads, freeing up team members to focus on value-adding tasks.

Felix Schoeller Group – Reducing administrative overhead in paper production Before their digital transformation, the Felix Schoeller Group spent significant time on admin-heavy tasks like writing meeting minutes. By combining mind mapping with task tracking in one integrated solution, they reduced admin time by 50%. Teams now link agendas, tasks, and decisions directly, making all project information accessible, transparent, and easy to follow up on.

These success stories show the tangible impact of digital tools like MeisterTask: structured continuous improvement, higher productivity on the shopfloor, and measurable progress toward ESG goals.

What makes a continuous improvement culture work

Tools like MeisterTask are essential, but they’re only one part of the equation. A sustainable CIP culture depends on people — their mindset, motivation, and willingness to embrace change. Here are the key success factors that separate one-off efforts from lasting impact:

Inclusive participation Everyone should have a voice in improvement efforts — from production to logistics, quality to maintenance. Make it clear that every idea matters and create a psychologically safe space where teams can contribute openly and without fear of judgment.

Leaders who lead by example Managers aren’t just decision-makers — they’re enablers. Their role is to remove roadblocks, provide meaningful feedback, and visibly support improvement initiatives. When leaders champion CIP, teams are more likely to engage.

Start small, celebrate early Don’t wait for perfection. Recognize and communicate small wins early on to build momentum. Quick wins show that the process works and help teams feel ownership and pride in continuous improvement.

Make retrospectives routine Reflection isn’t a nice-to-have — it’s a must. Regular retrospectives help teams learn from successes and setbacks, adjust strategies, and identify fresh opportunities to improve.

Track progress with meaningful metrics Use KPIs to measure success and guide your next steps. Common indicators include the number of implemented ideas, reductions in defect rates, or faster throughput times. Clear metrics make CIP tangible and sustainable.

Better every day — and here to stay

In manufacturing, continuous improvement isn’t just a best practice — it’s a competitive necessity. CIP helps you standardize workflows, reduce waste, and boost product quality. Inspired by Kaizen and Lean principles, it gains new power through digitalization and rising ESG expectations.

With a clear structure, engaged employees, and the right digital tools, you can future-proof your production processes — and achieve your environmental and social goals along the way.