Let’s face it: many tools weren’t built with manufacturing in mind. Disconnected systems, manual processes, and inefficient communication lead to costly delays, compliance risks and improvement initiatives that never stick.

MeisterTask is different. It's a scalable, intuitive operations project management software that brings structure and clarity to modern manufacturing teams. Here’s how.

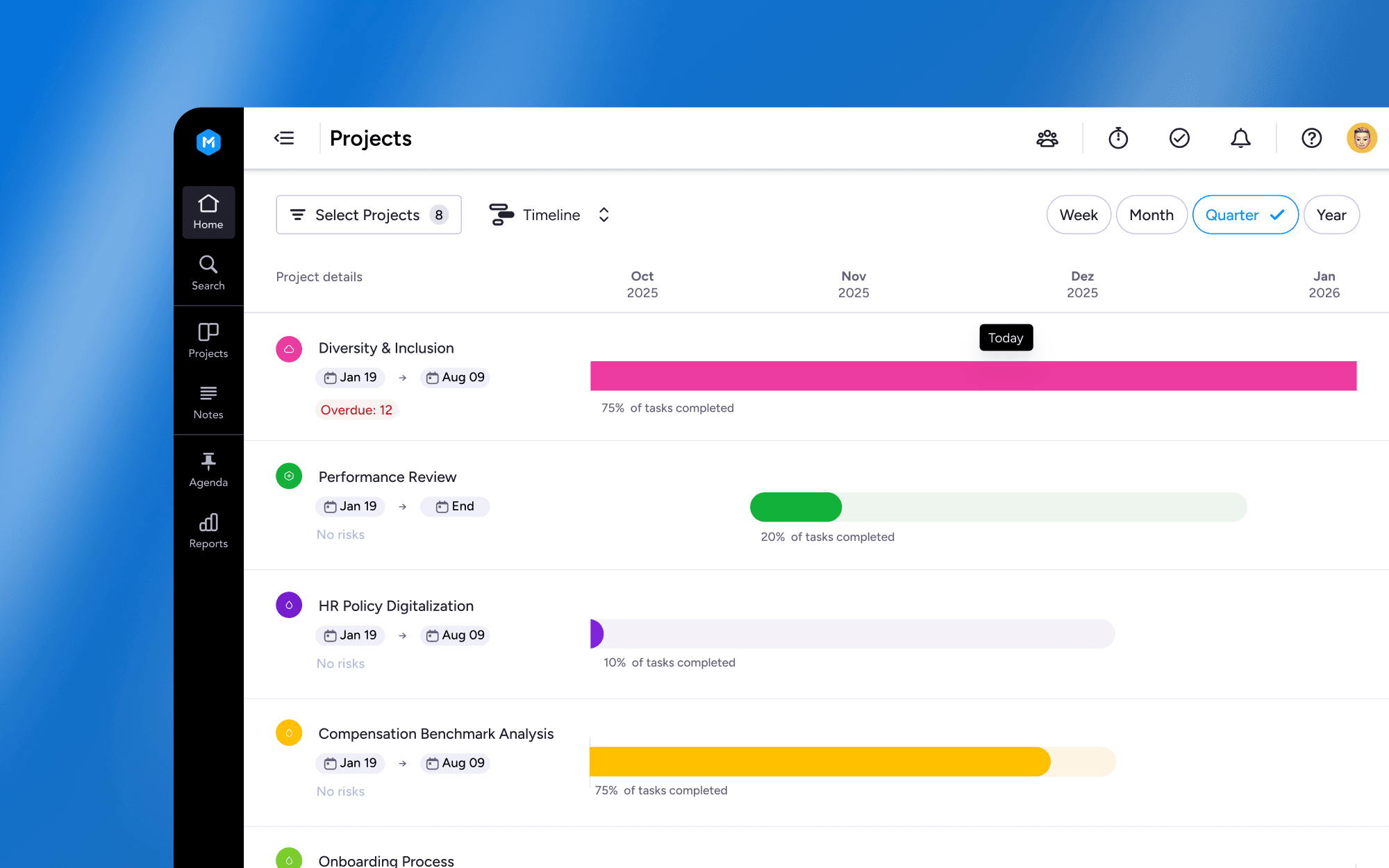

Manage multi-level projects across production and R&D

In technical manufacturing, successful product delivery depends on seamless coordination between R&D, prototyping, testing and production. But in many organizations, each of these teams works in silos — using different systems, reporting to different managers, and operating on mismatched timelines.

This disconnection across product lifecycles causes misaligned priorities, missed dependencies, and unclear ownership. Tasks fall through the cracks, and projects stall at critical junctures.

How MeisterTask helps:

Project hierarchies using sections and subtasks bring complex workflows into one centralized Kanban board. Each stage of development is broken down and clearly visualized.

Automations keep momentum going by triggering downstream tasks — e.g., once design is approved, production prep starts automatically.

Timeline view and Reports give leaders the big picture, helping them anticipate bottlenecks and manage resource allocation.

Streamline logistics coordination

Logistics operations are high-stakes. A delayed shipment or a lost purchase order can disrupt the entire production line. Yet many manufacturers still rely on spreadsheets, shared inboxes or static ERP systems to manage logistics — a setup that lacks real-time task ownership and traceability.

Without visibility into who’s doing what, when, or why, operations leaders struggle to prevent disruptions in supply chains or respond quickly when issues arise.

How MeisterTask helps:

Set up dedicated boards to manage everything from inbound materials to outbound delivery routes and vendor relationships.

Assign clear task ownership with deadlines and responsible roles, so nothing is left in limbo.

Use Notes for tracking documentation like customs forms, loading instructions, or vendor checklists.

An ERP system is a dinosaur compared to MeisterTask. It’s just far less agile. We’ve realized how helpful an auxiliary task management tool can be for a production facility like VERWO. Every workstation now has access to MeisterTask. We use MeisterTask to complement our day-to-day task management workflows.

BG

BGBeatrix Garai

Application Engineer, VERWO

👉 Learn how VERWO improved operational efficiency with MeisterTask

Operationalize kaizen with structure

Kaizen, Six Sigma, or other lean initiatives are essential for manufacturing excellence. But without a consistent system to document, track and follow up on improvements, these efforts fizzle out.

Often, great ideas shared during daily standups or Gemba walks never leave the room. The result? Teams become skeptical, and process improvements plateau.

How MeisterTask helps:

Create repeatable templates for kaizen workflows. From root cause analysis to corrective actions, each initiative follows a consistent structure.

Use Tags to categorize efforts — safety, quality, waste, etc. — and easily track trends across projects.

Schedule recurring tasks to keep continuous improvement alive, whether it’s daily standups or monthly improvement audits.

Make meetings actionable

In manufacturing operations management, meetings are necessary. But too often, they lack a clear agenda, generate no follow-ups, and drain time without producing results. Operations leaders end up spending hours in conversations that don't move work forward.

The true cost? Action items get lost, accountability disappears, and progress stalls.

How MeisterTask helps:

Create meeting boards that double as dynamic agendas and action logs.

Turn decisions into real-time tasks with due dates and assignees — so responsibilities are clear the moment a meeting ends.

Integrate with your calendar and Slack or Teams to make prep, execution, and follow-up seamless.

We use MeisterTask for departmental projects, as a basis for our Monday meetings, for shop floor management meetings and much more. When we put information in tasks, nothing gets forgotten or lost.

TS

TSTorsten Schlegel

Process Coordinator, Ritter Sport

Meet ESG requirements with confidence

Manufacturers face growing pressure to meet environmental, social, and governance (ESG) requirements — while maintaining strict compliance with industry regulations. But many struggle with fragmented systems that don’t support audit trails, permissions control or cross-functional coordination.

This makes it hard to show progress, pass compliance audits or meet investor expectations — especially as regulations become stricter.

How MeisterTask helps:

Set up dedicated projects for ESG initiatives like emissions reduction, energy audits, or supplier compliance.

Use role-based permissions to control access, ensuring only authorized stakeholders see or edit sensitive information.

Track and prove progress with reports and tags — ideal for demonstrating KPI achievements during audits or board reviews.

Your operations, simplified

Operational complexity is part of manufacturing. But disorganization, inefficiency and missed objectives don’t have to be.

MeisterTask brings the clarity and control that modern operations leaders need. Whether you’re optimizing production, managing logistics, driving kaizen or reporting on ESG, our manufacturing operations management tool has you covered.

With MeisterTask, you can:

Turn disconnected teams into one synchronized operation

Track logistics and supply chains with clarityEmbed kaizen into daily routines

Make every meeting count

Demonstrate compliance and ESG progress with confidence